Injection Molding Service

in China

- Going from prototype to production

- Rapid tooling, with multi-cavity mold available

- Low MOQ, competitive price, fast lead time

Injection Molding Services

As an experienced injection molding company, we can supply custom molded parts from plastic to rubber at a fast turnaround.

Injection molding is commonly applied to bridge tooling, pilot runs, functional testing, rapid prototyping, etc.

Plastic Injection Molding

As an experienced plastic injection molding manufacturer in China, we can produce a wide range of custom plastic molded parts, industries served cover medical, industrial, electronics, etc.

Rubber Injection Molding

In rubber molding, we are able to manufacture a variety of molded parts with expected finishes on demand. We have been dedicated to providing the most cost-effective injection molding solutions.

Overmolding & Insert Molding

Overmolding and insert molding are also two common injection molding processes. For example, toothbrush handles are over-molded parts, and insert molded parts include pulleys, fan blades, and so on.

Molded Parts Show

Gallery of Injection Molding Parts

We manufacture a variety of injection molded parts on demand, from tooling design & fabrication, sampling, to volume manufacturing.

We can accept complex designs and offer flexibly CNC machining, part marking and surface finishing on your demand.

We are your ideal choice for injection molding parts design validation and bridge tooling.

Post Processing Options

- Mold texturing (Mold-Tech)

- Thread inserting

- Gate Trimming

- Painting

- Part marking

Injection Molding Capabilities

- Maximum size: 480 x 751 x 203 mm

- Maximum volume: 966,837 cu. mm

- Wall thickness >= 1.5mm (0.06")

- Mold cavity: Single or multi-cavity

- Mold life: replacement without charge

Material Selection

Materials for Injection Molding

A wide range of more than 70 thermoplastic & thermoset materials can be selected in our custom injection moulding services.

And heat resistance , tensile strength, heat deflection, hardness and durability are the factors that should be considered for material selection.

In addition to this, we will also consider material costs and end use.

ABS is a thermoplastic which is resistant to corrosion, easy to process, and the melting point is relatively low.

It is primarily used in a variety of enclosures application.

Acetal is a high-performance thermoplastic that is low-friction and lightweight. It is well-used for a wide range of applications due to wear resistance and anti-corrosion.

Common application include gears, rollers, fasteners, bearings, bushings, dispensing components.

Common grades of acetal for injection molding, including:

- celcon M90

- 10% glass fiber filled acetal

- 20% glass fiber filled acetal

There is a wide selection of molded nylon materials, and the advantages vary due to its characters.

For example, nylon 6/6 has good mechanical strength, stiffness and wear resistance, while nylon 6 has extremely high hardness and toughness at low temperatures, and nylon 6/12 has better impact strength.

Nylon 66: with good tensile strength, wear resistance, and high temperature resistance.

Glass fiber filled nylon, such as with 15%, 20%, 33%, 35%, 40% fillers, which have high tensile strength and hardness, with high-temperature resistance.

Polyphthalamide (PPA) is a higher stiffness, strength, and thermal properties material with good creep resistance and stability.

It is well-suited for automotive, oil and gas, plumbing components applications.

HDPE is a thermoplastic made from petroleum, with high tensile and impact strength, and a high melting point.

It’s well-used for Caps and enclosures applications.

LDPE is a soft, flexible, tough, and lightweight material with good anti-corrosion, impact resistance, crack resistance.

Its low cost and durable properties make it a good material choice for molded parts, for example:

- Enclosures

- Caps

- Snap fits

- Lids

PBT has well rounded mechanical properties, It also has high heat and chemical resistance, which make it well used for applications as follow:

- Enclosures

- Switches

- Electrical

- Bobbins

There are three common grades of PBT for injection molding service such as Valox 357, Valox 420 SEO (30% GF), Crastin S600F20:

PEI is a translucent material. It has a very high dielectric strength and high temperature resistance properties that make it ideal for applications in medical instrument components and electrical insulation parts.

Due to its good mechanical properties, it is primarily used in

medical device parts and electrical insulation parts.

PEEK is a well-performance thermoplastic with good strength and ductility. It also conforms to FDA standard for food contact and other medical applications.

As an inert material, PEEK has a wide range of applications for plastic injection molding parts in the medical, petroleum, and aerospace industries due to its chemical resistance.

Polyvinyl Chloride has mechanical and electrical insulation properties with high hardness. It is resistant to many chemical liquids.

It is often used for the follow parts:

- Medical containers,

- Constructions,

- Piping,

- Cables

Two regular grades of PET available in our molding service such as Rynite 530 (30% GF) and Rynite 935 (35% GF).

Its key benefits include dimensional stability, lightweight, durable, and stiffness.

Its properties make it an ideal choice for components in electronic, and automotive industries.

Polysulfone is an amorphous and natural transparent thermoplastic.

Two regular grades of PSU for the injection molding service, Udel P-1700 and Udel P-3703.

PSU is a ideal choice for molded parts that will have to endure high temperature.

Its chemical resistance and compliance with gamma sterilizing requirements also lends its well suited for medical devices and components, dental parts, surgical instruments.

Acrylic(PMMA) is a transparent polymer with good tensile and flexural strength. It costs less and has comparable properties to polycarbonate.

It is well used for lenses,

tail light covers, light transmission parts.

Key benefits as follow:

- High clarity

- Dimensional stability

- UV Resistance

- High heat resistance

Thermoplastic Elastomer (TPE) is a thermoplastic but it has the look and feel of a rubber-like, meaning it can be re-melted. It is predominantly used for automotive applications, household appliances due to its good thermal properties and stability at a wide range of temperatures.

LLDPE, linear low-density polyethylene, is a thermoplastic material with good flexibility, even at low temperatures, impact resistance and puncture resistance.

LDPE molded parts are usually used for lids, containers, tubing, and other consumer products.

Thermoplastic polyurethane (TPU) is a flexible material with abrasion resistance, chemical resistance, impact strength, and overall good toughness.

Available two common grades of TPU for injedction molding, Texin 245D and Texin 983A.

It is well suited for parts such as wheels,hoses, gaskets, footwear.

Polypropylene is inexpensive and easy to access, well suited for wide range of applications, including the packaging of consumer products as well as plastic components.

Because of its relatively low density and weight, it can also be used in a variety of molded products such as:

- Children’s toys

- Sporting goods

- Caps

- Household goods

Polycarbonate (PC) has extremely well impact resistance, scratch resistance, and heat resistance with low shrink with good dimensional stability and accepts high cosmetic requirements well.

There are various grades of PC for the plastic injection molding process, including Lexan, Makrolon, Hylex, RTP.

DFM Tips for Injection Molding

Wall Thickness

Uniform wall thickness is necessary, otherwise it will influence the mechanical performance, cosmetics of the injection molding parts.

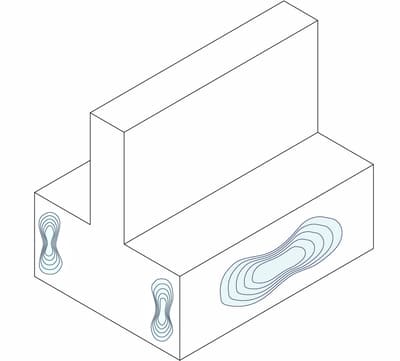

Ribs

The ribs are prone to generating sink marks. Therefore, the wall thickness of ribs have got to be significantly reduced if possible.

Undercuts

Undercuts in injection molding make it difficult for injection molded parts to be ejected. This should be avoided during manufacturing.

Parting Line

The location of the parting line should be considered carefully.

Avoid to set fillets around the parting line, otherwise it will lead to unwelcome defects in the mold.

Ejector Pins

When the injection molded part finishes cooling, the part is ejected from the mold by the ejector pin, and in most cases there will be ejector marks that should be avoided.

Multi-cavity Mold

Multi-cavity injection molds can save costs because more injection molded parts can be produced in one production cycle, and productivity increases exponentially.

C-Shaped feature

Due to the inherent weakness of C-shaped parts, should be cautious with C-shaped injection molded parts, as they maybe warp even more, compared to unfilled material.

Draft Angle

A properly designed draft angle, and applying it when tooling design will make the injection molded parts to be released easily from the mold without prying them out.

Use radius correctly

Use radii only necessary, for example, to remove sharp edges. In general, proper usage of radii during injection molding can improve the strength of the molded parts.

Why Choose Us For Injection Molding

DFM Tips

As you known that most injection molding suppliers in China can only customize parts as per drawings, lack of technical advice and cost saving methods.

We, on the other hand, can offer DFM tips and optimized injection moulding solutions.

quick quote

We have the ability to quote quickly, and submit it within 24 hours. Shipping costs and lead time will also be estimated in real time for your reference.

scalability

We have the flexibility to support you from tooling design, rapid prototyping to batch manufacturing, and support to design multi-cavity mold according to the actual requirement.

responsibility

Each order is subject to at least two quality checks to ensure high-quality delivery, and every work given by the customer is completed carefully and the work progress is kept informed in anytime.

Versatility

With a full range of injection moulding capabilities, we can offer you one-stop custom injection molding services with diverse surface finishes to meet your cosmetic needs.

competitiveness

Every stage, from raw material sourcing to production and quality control, is optimized to achieve the best cost control in the injection moulding industry, while we maintain only the lowest reasonable profit to sustain company operations.

Surface Finish for Injection molded parts

| Glossy | Semi-Gloss | Matte | Textured |

|---|---|---|---|

| SPI A1, SPI A2, SPI A3 | SPI B1, SPI B2, SPI B3 | SPI C1, SPI C2, SPI C3 | SPI D1, SPI D2, SPI D3 |

*Additional notes on finishes:

Draft angle will vary depending on the required finishes. Material color matching will be based on the RAL color chart.

Surface finish grades for injection molded parts that comply with SPI (Society of the Plastics Industry) standards go from the least refined to the most refined and are classified as follows:

- Grade A – Glossy, finishing with grit diamond

- Grade B – Semi-gloss, finishing with grit paper

- Grade C – Matte, finishing with grit stone

- Grade D – Textured, finishing from the dry blast with glass beads

The Injection Molding Process

Learning more about the injection molding process will help to make the necessary considerations in designing injection molded parts and how to plan production schedules.

STEP 1

DESIGN 3D MODEL

Choose colors, textures and materials, and define dimensions and structure to generate 3D model.

STEP 2

DESIGN VERIFICATION

Rapid prototyping will be applied to test injection molded parts for compliance with functional, strength, aesthetic requirements.

STEP 3

DFM ANALYSIS

The purpose of this stage is to learn more about all the potential risks or issues for tooling design and injection molding, and is to verify the feasibility of the CAD design.

STEP 4

TOOLING DESIGN

After DFM demonstration, start tooling design and injection moulding manufacturing.

At this stage, should be ensured that make as no or only small modifications as possible.

STEP 5

T1 SAMPLES TRIAL

T1 samples are prepared and sent to customers for testing.

If T1 samples do not meet the requirements, adjustments and improvements need to be made accordingly.

STEP 6

T2 & T3 SAMPLES PLAN

T2, or T3 sample plan will be executed depends on actual needs.

STEP 7

KICK OFF PRODUCTION

After samples’s approval, it’s time for kicking off production.

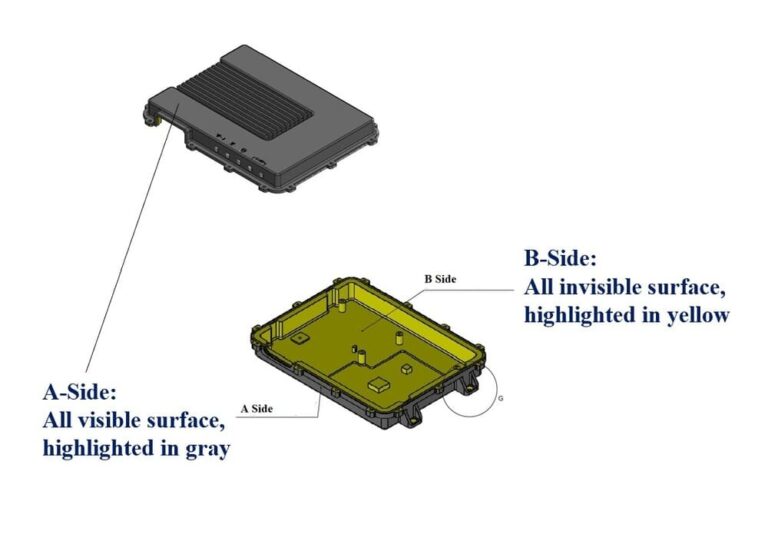

Definition of A & B Side

When designing injection molded parts, the different finish requirements of its cosmetic side and functional side should be considered and balanced against their end use.

The critical surfaces should be as defect-free as possible, while minor defects on secondary surfaces should be minimized.

The two surfaces of injection molded parts normally have different purposes.

Side A, the side facing the cavity, is known as the cosmetic side and is usually the visible outer surface. This side should be smooth or have the required texture.

Side B, the back half of the mold, is known as the functional side and normally contains some structural elements that can be hidden after assembly (e.g. bosses, ribs, etc).

This side will normally have minor defects similar to ejector pin marks.

Common defects of Injection Molded Parts

Most defects in injection molded parts are related to uneven or inadequate flow and solidification of the molten material, from being filled to being cooled.

Therefore, the first priority is to ensure good design.

Some common defects in injection molding are listed below and should be carefully considered and avoided during designing and manufacturing.

Sink marks

When the surface of an injection molded part is solidified posterior to its interior, small sink marks may appear on the surface here.

Most of the defects of sink marks are caused by uneven wall thickness.

Two effective ways to solve this problem are adding ribs and coring out of thick area.

Drag marks

The shrinkage that accompanies cooling during solidifying can exert some pressure on the mold.

When the molded part is ejected from the mold, drag marks occur due to its walls scraping against the mold.

Typically, the injection molded parts designed without a draft angle (with vertical walls) are most likely to lead to these defects.

Warping

When different sections or areas of the injection molded parts are cooled unevenly (certain sections are cooled slower than others), then the parts will bend under the action of internal stresses.

Non-constant wall thickness design is the major cause of bending.

Flash marks

Flash marks can affect the effectiveness of sealing and assembly.

This type of defect usually occurs when excess molten material spills out of the mold cavity, and mainly at the parting line or ejector pin position.

Knit lines

Inside the mold, small stripes (called knit lines) with discoloration may occur when two streams of molten material meet.

These stripes not only interfere with the visual appearance of the molded part (which is deemed unacceptable for aesthetically demanding cosmetic parts) but also affect its performance to some extent.