Part Marking Service

- Part marking on demand

- Make part marking easy and efficient

- Value-added service available with cost effectiveness

Part Marking Service

Part marking is a common way to add logos or lettering to your designs.

For part marking, the following is required:

- 3D drawing

- A vector file with the required content for the marking, indicating the specific style

- 2D drawing indicating the exact location for the marking

We are familiar with various marking processes of the Mil-Std marking specification.

You can be completely assured that parts will be marked in accordance with the specification’s marking requirements.

We would like to show you our part marking capabilities by providing you with marking samples.

Our part marking capabilites

Laser engraving and pad printing are two economical part marking techniques that can give you more flexibility in your designs.

They are a great option especially for marks that are not easy to make by tooling, rather than designing it as part of a model.

Laser engraving

Laser engraving is a very fast and effective non-contact marking method. It is frequently used for part marking due to its speed and accuracy.

According to the color of engraving, it can be divided into traditional and color laser engraving

The laser engraving marks the part in a way that does not wear off over time, this make it useful when printing logos or serial numbers on custom parts.

Pad Printing

Pad printing, is an indirect offset printing process that can transfer a 2-D text or image onto a 3-D object.

With pad printing technology, it is possible to print a variety of difficult shapes, such as curved or convex, hollow or concave, cylindrical, spherical, textures, that are not available with traditional printing processes.

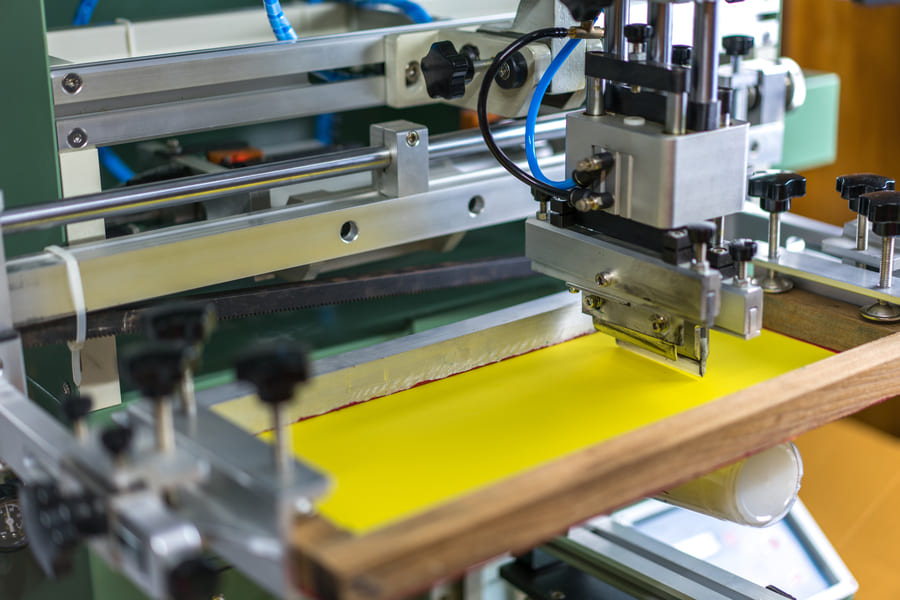

Screen Printing (Silk Screening)

Screen printing is a relatively inexpensive option for marking parts and is used in a variety of industries.

Because it allows a wide choice of colors and is applicable to a wide range of materials, such as metals, wood, ceramics and plastics.

Screen printing is also used for various type of substrate (including flat or uneven surface).